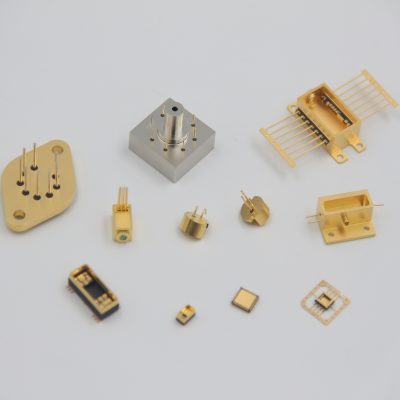

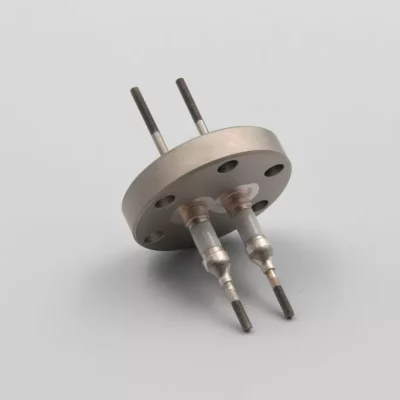

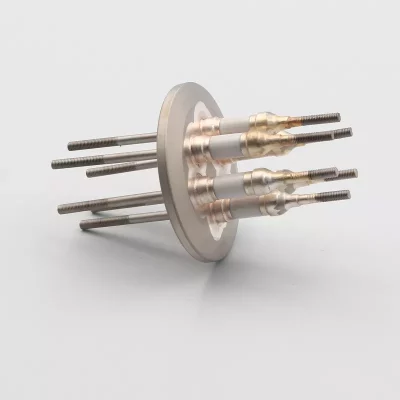

InSealing produces metalized ceramic, and ceramic feedthrough used in military, aerospace, medical, and high-reliability industrial applications. Ceramics are extremely reliable in high vacuum applications and compatible with metals such as Titanium, AlSi, Kovar, Ally42, CuMo, and CuW.

Metallized ceramics, Ceramic feed-throughs can support high-frequency applications up to 30GHz and offer a coplanar surface for wire bonding.

Ceramic Material is 96% Alumina

| No | Item | Unit | Value |

| 1 | Purity | % | ≥95 |

| 2 | Volume density | g/cm3 | ≥3.6 |

| 3 | Water absorption | % | 0 |

| 4 | Thermal conductivity | W/m·K( 25℃) | 22.4 |

| 5 | Coefficient of thermal expansion | X(10-6)/℃ (20-1000℃) | 8.2 |

| 6 | Flexural strength | Mpa | 340 |

| 7 | Compressive strength | Mpa | 2103 |

| 8 | Tensile strength | Mpa | 193 |

| 9 | Hardness | ROCKWELL 45N | 78 |

| 10 | Withstand voltage | K Vac/mm | 8.3 |

| 11 | Dielectric constant | @1MHz | 9.1 |

| 12 | Dielectric loss angle | @1MHz | 0.0004 |

| 13 | Volume resistivity | @25℃ | 1×10-14 |

| @500℃ | 4×10-9 | ||

| @1000℃ | 5×105 |

Ceramic Metallization Layer:

- Ceramic + Mo/Mn Metallized + plating Ni

- Ceramic + Mo/Mn Metallized + plating Ag

- Ceramic + Mo/Mn Metallized + plating Au

- Ceramic + printing Ag

- Other Custom Metallization Layer as requested.

Type of Plating:

- Electroless Gold

- Electrolytic Gold

- Electrolytic Nickel

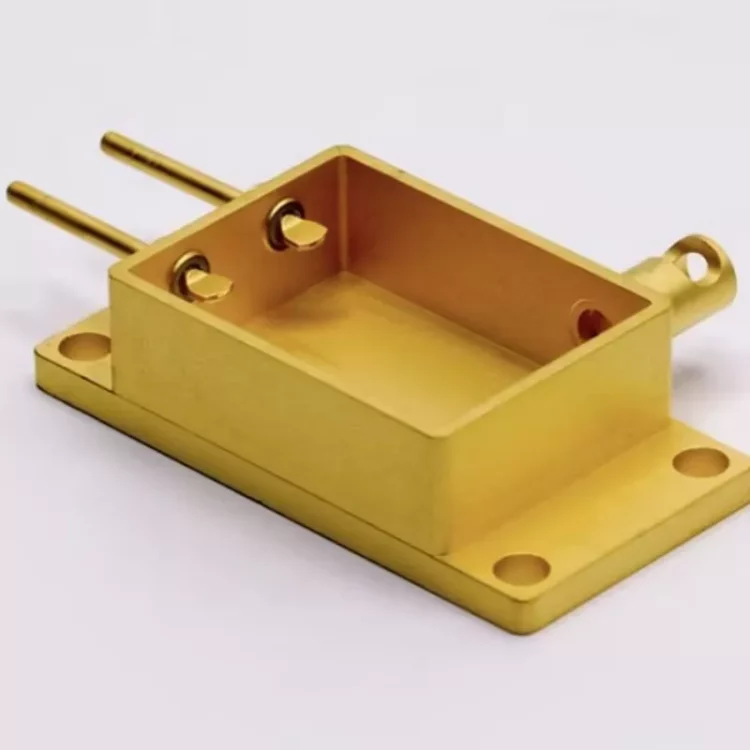

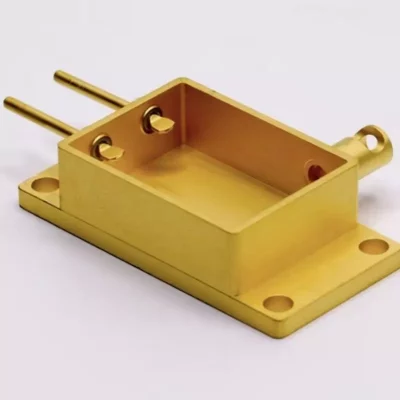

Brazed Component Materials:

- Alloy 194

- Alloy 42

- Copper Alloy

- Kovar

- Molybdenum

Applications:

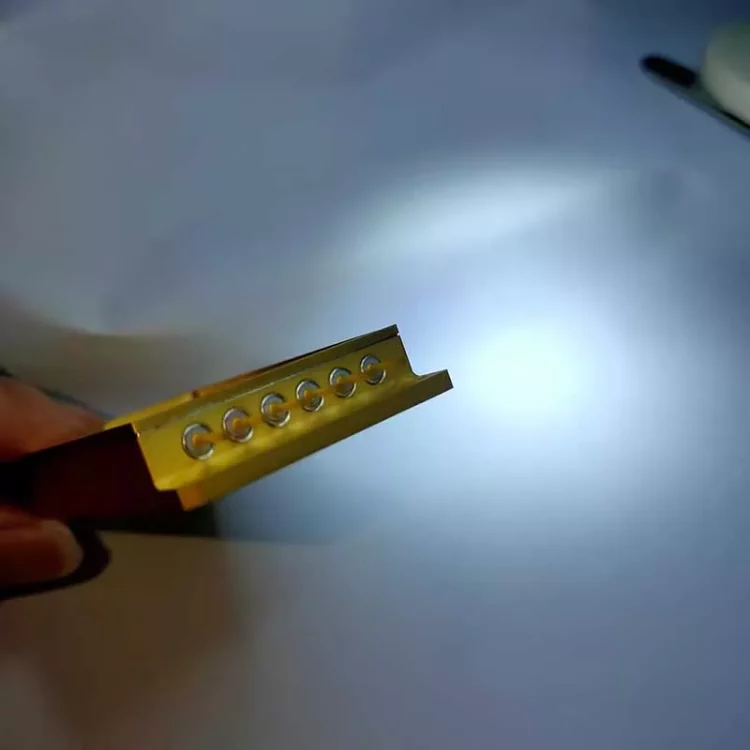

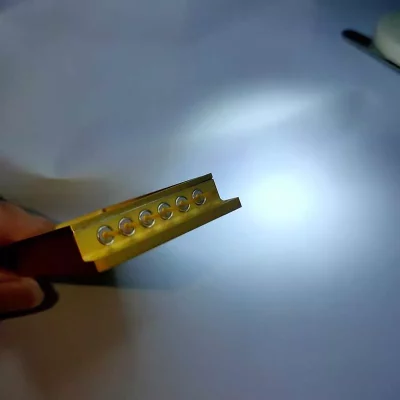

- Optoelectronic Packages

- Hermetic / High-Frequency Feedthroughs

- Ceramic/Metal Packages

- Microwave Packages

- Multichip Modules

- Power Dissipation Packages

- Optical Packages

- High Lead Count Packages