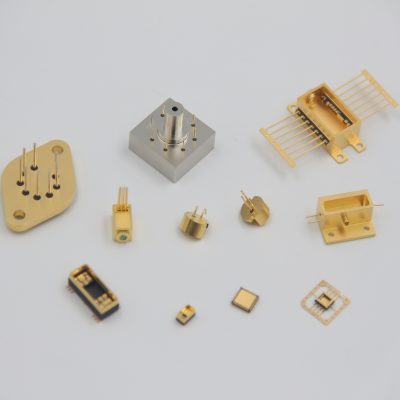

Ceramic to metal feedthroughs are custom assemblies for the passthrough of substances or energy from outside a hermetically-sealed chamber to the inside. They provide hermeticity and electrical isolation and remain leak-free in high and ultra-high vacuum.

Types of feedthrough:

- Feedthroughs for low voltages (up to 12 kV)

- Water-cooled feedthroughs and RF feedthroughs

- High-voltage feedthroughs (20 to 100 kV)

Applications :

- Semiconductor processing equipment

- Particle accelerators

- Furnaces

- Analysis equipment

- Coating applications in vacuum environments

- Satellite instrumentation

- X-ray equipment

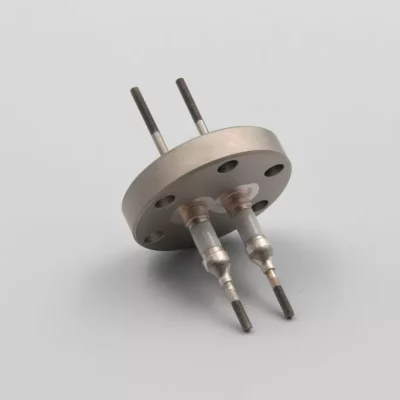

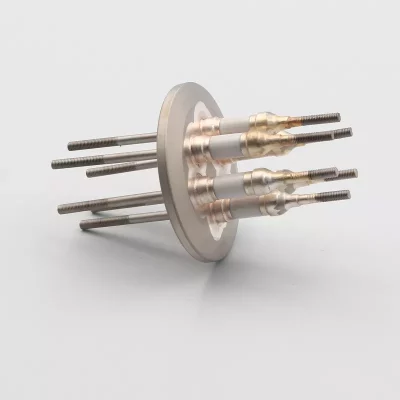

Ceramic-to-metal feedthroughs use only inorganic materials.

The insulators are made from alumina ceramics which is high-purity, high-strength, low-loss.

Metals include Kovar, stainless steel, nickel, copper, nickel-iron alloys, cupro-nickel alloys, molybdenum etcs.

Braze materials used are silver, copper, silver-copper, or gold-copper alloys.

Metalization processes include both refractory-metal and active-metal metalizations, depending on the size, geometry, and performance requirements for the feedthrough.

Standard installation mountings for feedthroughs include:

Brazing

Welding (pulse-TIG, TIG, laser, E-beam welding)

ISO KF flange

ConFlat flange

NPT fitting

1″ baseplate

If you have any request, just contact with us.