Ceramic-to-metal assemblies are integral components in various industries, especially in sectors like electronics, aerospace, automotive, and medical devices. These assemblies are designed to provide a reliable interface between the delicate electronic components or sensors housed within ceramic materials and the external environment.

The primary purpose of ceramic-to-metal assemblies is to provide a hermetic seal or electrical insulation between the ceramic and metal parts. This is essential for protecting sensitive electronic components from environmental factors such as moisture, dust, and chemicals.

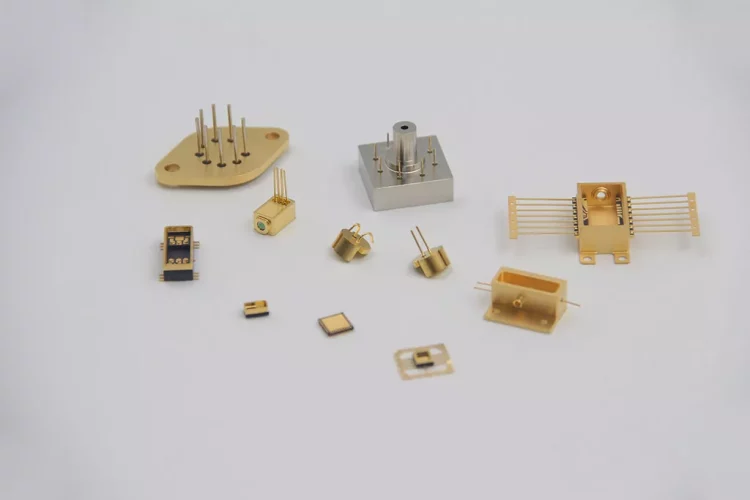

Typically, these assemblies consist of a ceramic component (such as alumina or zirconia) and a metal component (such as stainless steel, Kovar, or titanium). The ceramic component provides electrical insulation and thermal stability, while the metal component provides structural support and facilitates connections to external systems.

The manufacturing process for ceramic-to-metal assemblies involves precision machining of ceramic and metal parts, followed by assembly and sealing processes. Techniques such as brazing, laser welding, or adhesive bonding are used to create a robust bond between the ceramic and metal components while maintaining hermeticity.

2023-09-19

In the era of cutting-edge technology, hermetic sealing plays a pivotal role across various domains. Whether it's particle physics, neutrino research, microwave windows, optical windows or lenses, X-r...