Let’s be real. Fancy laser systems and high-speed communication devices get all the glory. But what about the components that make them work? The ones that do the hard job in the background?

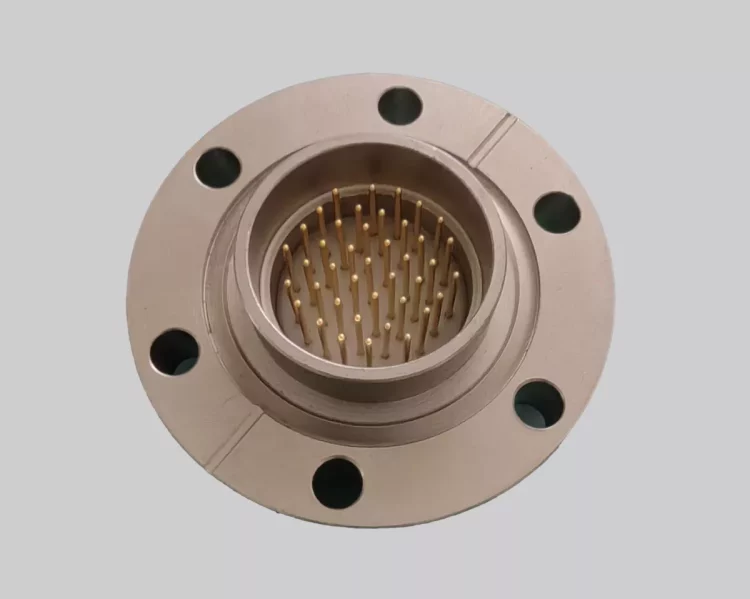

I’m talking about the Multipin Vacuum Feedthrough.

It’s not the most glamorous part. But without it? Many of our advanced photonic systems would simply fail. As someone who works with ceramic-to-metal sealing every day, I can tell you—this little component is a masterpiece of engineering.

So, what does it do? In simple terms: it creates a bridge. It’s a special connector that lets multiple electrical signals or power lines pass through the wall of a vacuum chamber. And it does this without breaking the seal. Not even a tiny leak. That’s the magic.

Why Photonics and Communications Need This

In the world of photonics and communications, we’re often dealing with super-sensitive components sealed inside a vacuum or a special protective atmosphere.

Why a vacuum? It keeps things clean. No dust. No moisture. No corrosive gases to interfere with the delicate internal workings. This is absolutely critical for the performance and lifespan of devices like high-power laser diodes, photomultiplier tubes, and optical sensors.

But here’s the problem: these devices inside the vacuum need power. They need to be controlled. And they need to send data back out. You can’t just run a bunch of wires through a hole—that would destroy the vacuum.

This is where the Multipin Vacuum Feedthrough comes in. It’s the critical link. It allows the “outside world” to talk to the “inside world” without compromising the environment.

The Ceramic Secret: How It Actually Works

This is where my expertise in ceramic brazing comes in. The heart of a reliable feedthrough is the seal. It’s not just glue or epoxy.

We take a metal pin—usually something like Kovar® because it expands at a similar rate to ceramics. We then braze it into a precision-made ceramic insulator, often high-purity alumina (Al2O3). This ceramic is a superstar. It’s an incredible electrical insulator, even at high voltages, but it’s also a great thermal conductor, helping to manage heat.

Finally, we braze this entire ceramic-pin assembly into a metal flange. The brazing process creates a permanent, ultra-high strength bond—atomically bonding the ceramic to the metal. The result? A seal that is:

Hermetic: Absolutely leak-tight. It maintains a perfect vacuum for years.

Robust: It can withstand wild temperature swings, from cryogenic cold to high heat. Many can even be baked out at high temperatures to de-gas the vacuum chamber.

Reliable: It won’t degrade over time. This is non-negotiable for multi-million dollar equipment.

Where You’ll Find Multipin Vacuum Feedthroughs in Action

Think about these applications:

Laser Manufacturing: Inside the chamber where laser crystals are grown or where laser diodes are packaged. The feedthrough provides power to heaters and controls for sensors.

Particle Accelerators & Research: These massive machines are full of vacuum tubes. They need thousands of electrical connections for sensors and magnets—all fed through using multipin feedthroughs.

Satellite Communication Systems: Before launch, components are tested in space simulation chambers that replicate the vacuum of space. Multipin feedthroughs are essential for running these tests.

In short, if you’re working with any photonic or communication technology that requires a sealed environment, you need a reliable way to get electricity in and out.The Multipin Vacuum Feedthrough is that solution. It’s a small part. But it enables big things.